World-Class Manufacturing Facility

Built for Precision, Quality, and Global Standards

Where Innovation Meets Reliability

Our advanced production lines and certified processes ensure safe, high-quality medical devices for healthcare providers worldwide.

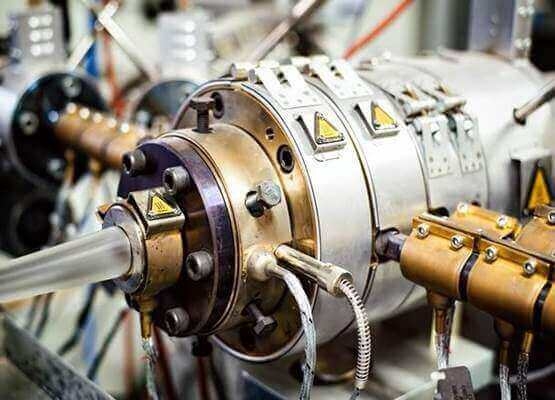

TPU Extrusion

TPU extrusion is the process of shaping Thermoplastic Polyurethane into flexible, durable tubing and catheters. Known for its strength, elasticity, and biocompatibility.

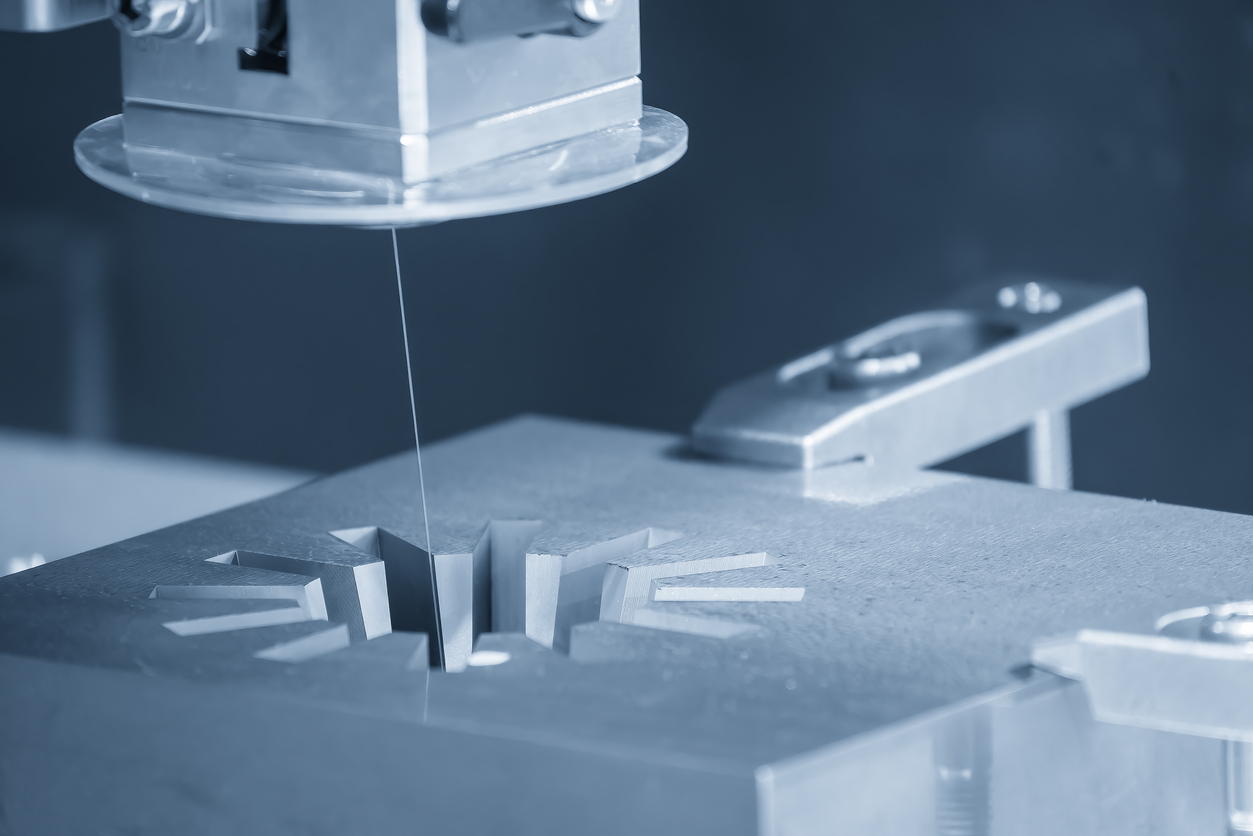

Plastic Injection

Plastic injection molds medical-grade plastics into precise parts and components. This process ensures high-quality, durable, and accurate medical devices with consistent shapes and dimensions.

Blister Packing

Blister packing seals medical products in clear, protective plastic for safe, sterile storage and easy use. It ensures product integrity and tamper resistance.

ETO Sterilization

ETO (Ethylene Oxide) sterilization uses low-temperature gas to effectively sterilize medical devices, ensuring they remain safe, sterile, and ready for patient use without damaging sensitive materials.

Thermal Forming

A tipping machine shapes and seals the ends of medical tubes or catheters with heat, creating smooth, safe tips for patient comfort and precise use.

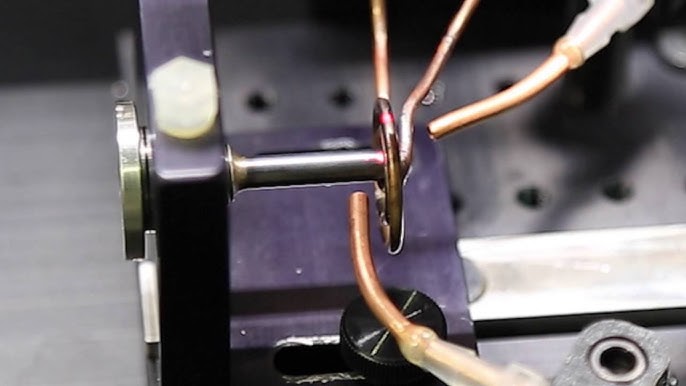

Micro Coiling

Micro coiling creates tiny, precise metal or polymer coils used inside medical devices like catheters or guidewires, adding flexibility, control, and strength for delicate procedures.

Ultrasonic Cleaning

Using high-frequency sound waves to remove contaminants, ensuring medical devices are thoroughly cleaned and safe for use.

Coating

Coating adds a smooth, protective layer to medical devices and components. Improving surface finish, reduces friction, enhances biocompatibility.

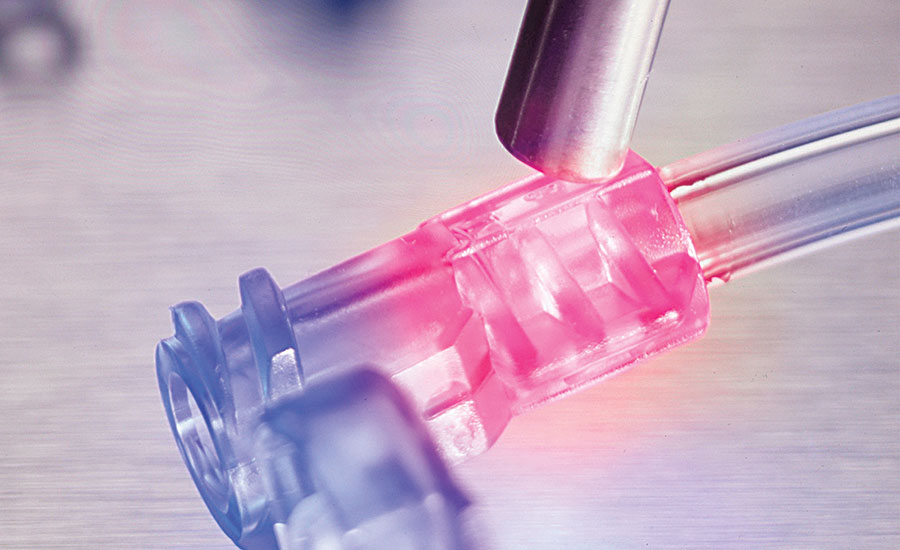

UV Bonding

UV bonding uses ultraviolet light to quickly cure adhesives, creating strong, precise seals on medical devices. Ensuring secure, clean joints without heat damage.